In addition to blade type, fans are typically organized by arrangement and operating characteristics. For most commercial and industrial applications, fans can usually be grouped into either housed-type fans or plenum-type fans. Each group has particular qualities which lend themselves to preferred or “best suited” applications. In order to understand these key operating characteristics, it is necessary to understand the fundamental differences in arrangements.

Note that although it is important to recognize the operating characteristics of stand-alone fan arrangements, fan efficiency and performance ultimately will depend on the surrounding equipment and intended application. For example, when comparing static efficiency, FC fans have a range of 60 to 80%, AF fans have a range of 75 to 80%, and axial fans have a static efficiency in the range of 70 to 72%. However, the fan selected should be the one that will best satisfy the airflow requirements of an application or fan system, while requiring the least amount of input power.

Plenum Fan

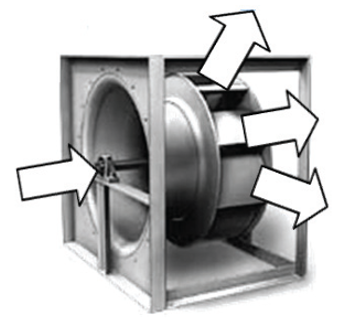

Another fan arrangement used in HVAC equipment is the plenum fan. Plenum fans are fans without housings that discharge freely into a plenum space. They discharge air in all directions rather than having flow directed as with a housed fan. (See Figure 8.) These fans have traditional BI or AF type blades and are almost always of the single-width, single-inlet (SWSI) type. The fans are employed directly in a discharge space, or plenum, and pressurize this plenum during operation. By pressurizing the plenum or cabinet, plenum fans create static pressure at the discharge openings of the plenum, eliminating the requirement for uninterrupted duct run to achieve optimal flow. Typically, these fans have a larger wheel spinning at higher speed to reach a pressure and flow comparable to that of a housed fan.

Plenum Fan Application Considerations

Plenum fans are best suited for applications requiring a high degree of flexibility in the fan discharge connections. Since the fan wheel is open inside the plenum or section, the fan creates static pressure inside the fan cabinet providing a relatively even distribution of airflow. One or multiple discharge connections can be made from the fan section as long as the connections are made downstream of the fan wheel and do not interfere with the integral supports of the fan.

Plenum fans, due to their heavy construction and airfoil type blades, are capable of high static pressures across the fan. While this high pressure capability can be very useful, it comes at a cost. Plenum fans generally operate at higher speeds and often have larger wheels than their housed fan counterparts.

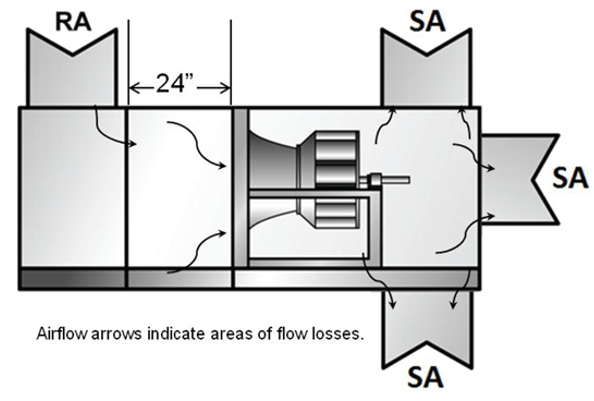

While plenum fan discharge location flexibility makes them more desirable, discharge duct or exit losses must still be considered. (See Figure 9.) Plenum fans, as well as other AHU components, can experience airflow issues if the space immediately upstream of the plenum fan is not properly addressed. The area approximately 24 inches immediately upstream of a plenum fan will not experience uniform full cabinet face area flow. Any component within this area may experience localized high-velocity airflow. This can become an issue for many system components, especially a cooling coil. For example, if a cooling coil were located within 24 inches of the plenum fan inlet, the resulting localized high velocity airflow may cause moisture carryover since the coil face velocity will exceed the recommended 500 to 550 fpm.

Housed Fan

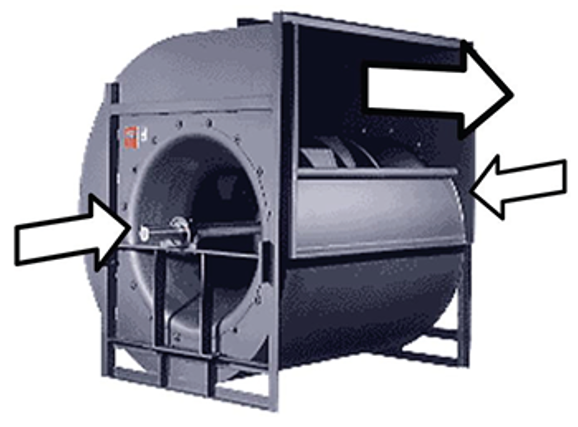

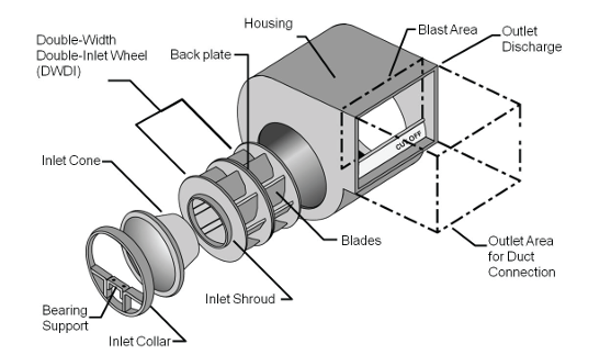

The most common fan used in the HVAC industry is the centrifugal fan. This design is comprised of a blower wheel and the surrounding scroll, often referred to as the fan housing. The fan housing controls the flow of air in a desired path, exiting at a discharge as shown in Figure 1.

Housed centrifugal fans utilize either FC or AF type wheels. In larger applications, there is often more than one inlet per wheel in a fan housing. The most common configuration is the double-width, doubleinlet (DWDI) construction, which has two wheels side by side sharing a common back plate. (See Figure 2)

Housed Fan Application Considerations

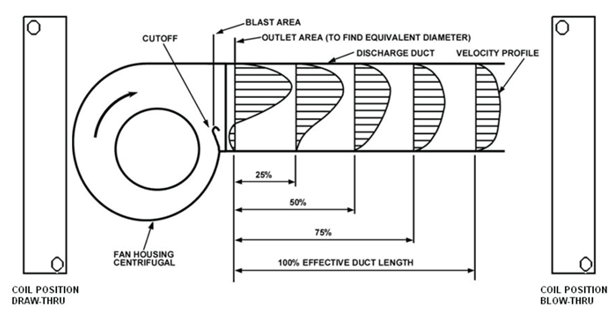

When using a housed fan, consideration must be given to the possibility of system effect and the discharge ductwork must be designed appropriately to minimize this effect. Since the velocity profile at the outlet of a housed fan is not uniform, adequate straight duct distance must be allowed for the velocity profile to fully develop. (See Figure 3.) If a turn or bend in the duct takes place before this distance, the fan’s external static pressure (ESP) capability will diminish.

With regard to the cooling coil location, the draw- thru configuration offers three advantages. First, the air is evenly drawn through the cooling coil and no dissipation means are necessary. Second, the cool higher density air results in better fan performance. Third, with the most common vertical discharge configurations, the fan discharge is attached to the duct and the velocity profile is dissipated in the duct. No discharge dissipation means are necessary.

In a blow-thru configuration, discharge airflow of a housed fan may also require a means to properly dissipate the discharge air before the air comes in contact with a filter or coil, ensuring the air is spread evenly across the available face area. This dissipation is normally accomplished via a diffuser, which generally adds section airway length to a unit and possibly additional cost.

Related Posts:

The Working Principle and Operation of Centrifugal Blower

Blowers are one of the mechanisms used regularly in submarines. They are installed in ventilation and air conditioning systems in almost all submarine compartments. Ventilation systems usually…

Centrifugal Fan Performance Curves

As you have known, you must know what the capacity of a fan is before you consider opening a damper or increasing the fan speed. Doing so may not be safe—it could result in an overloaded motor…