Centrifugal –Operating principle is a combination of deflection by the blades as well as the centrifugal force exerted on the air rotating with the wheel and thereby moving outward in a radial direction.

Axial and centrifugal fans have overlapping capabilities in terms of pressure, airflow, and efficiency; however, usually they are not interchangeable. For the same impeller diameter and speed, a centrifugal fan produces more static pressure than an axial flow fan.

Key Characteristics

- A centrifugal fan moves air and creates pressure partly by centrifugal action and partly by rotating velocity. The centrifugal forces are created by a rotational air column, which is enclosed between the blades of the fans.

- Air flow can be varied to match air distribution system requirements by simple adjustments to the fan drive or control devices

- Typically exhibit non-overloading characteristics except for forward curved centrifugal fan

- Commonly used in applications which require higher pressures

- Air flow through a centrifugal fan cannot be reversed

- Predominant choice for ducted applications because of their quite operation and availability in the low to medium pressure range of HVAC applications

- Frequently used in “dirty” airstreams (high moisture and particulate content), in material handling applications, and in systems at higher temperatures

- Can be constructed to accommodate harsh operating conditions

- Fans for industrial ventilation typically operate against pressures up to 22 in-wg; heavy-duty fans can achieve 55 in-wg or more

- The largest fans may have impeller diameters of 200 inches or more, and may handle more than 100,000 CFM

- Most versatile; their benefits include:

- Compact dimensions

- Quiet in operation

- Ability to overcome high system resistance

- Available in a wide range of sizes and motor speeds

- Can be tailored to suit specific applications

The four basic types of centrifugal fans distinguished by the angle of the impeller wheel blades.

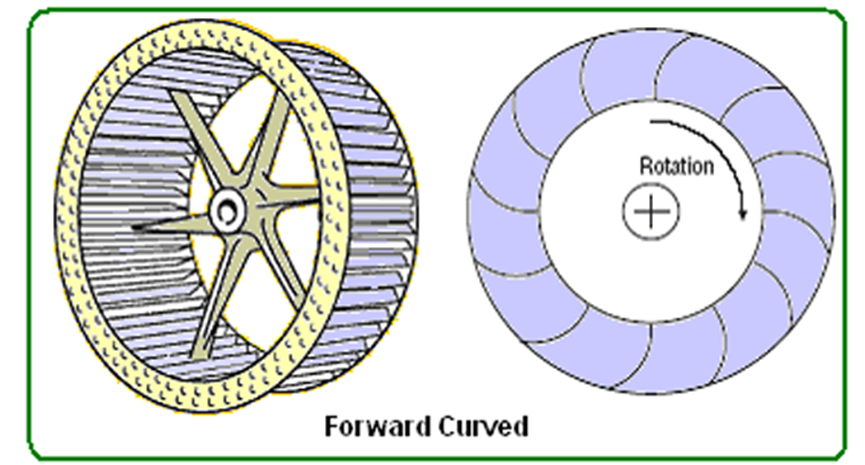

Forward-curved fans

Sometimes called “squirrel cage” fans, have blades with leading edge curved toward the direction of rotation.

- Usually contain 24 to 64 impeller blades

- Air leaves the impeller at velocities greater than the impeller tip speed i.e. air tip velocity > wheel peripheral velocity

- Best suited for moving large volumes at low static pressures for the same speed and wheel size

- Operate at lower speed than other centrifugals, which make them quiet

- Smaller size relative to other fan types

- Lighter in construction and less expensive

- Because these fans generate high airflow at relatively low speeds, these require a relatively accurate estimate of the system airflow and pressure demand. If, for some reason, system requirements are uncertain, then an improper guess at fan rotational speed can cause under performance or excessive airflow and pressure.

- Characterized by relatively low efficiency between 55 and 65 percent and is somewhat less than airfoil and backward-curved fans.

- Well suited for low pressure heating, ventilating, and air conditioning applications such as domestic furnaces, central station units, and packaged air conditioning equipment from room type to roof top units.

- Exhibit ‘overloading’ power curve characteristic i.e. the power increases steadily with airflow toward free delivery; consequently, careful driver selection is required to avoid overloading the fan motor.

- Fan output is difficult to adjust accurately and these fans are not used where airflow must be closely controlled.

- Usable only with clean air applications because blades easily accumulate dirt

- Not constructed for high pressures or harsh service

- Not recommended for fumes or dusts that would stick to the short curved blades because they would cause unbalance and would make cleaning difficult

Radial fans

Radial fans have blades, which extend straight from the shaft, and typically have 6 to 16 blades.

- Simplest of all centrifugal fans and the least efficient. Radial fans have efficiencies of 50 – 65 percent

- Operate at medium speed and can move air against higher pressures than other centrifugal fans. Pressures up to 55in-wg are common; custom-designed fans can achieve pressures over 100in-wg

- Produce high sound levels with pronounced blade passage tones at high pressure applications

- Usually have medium tip speed and noise factor and are used for buffing exhaust, woodworking exhaust, or for applications where a heavy dust load passes through the fan

- Exhibit ‘overloading’ power characteristic i.e. horsepower rises with increasing air quantity in an almost directly proportional relation

- Less prone to clogging and minimize contaminant build-up. Especially suited for conveying “dirty” airstreams and in material handling applications

- Because of their simple blade shape, these can be ruggedly constructed with expensive alloys that are strong and corrosion resistant, or they can be less expensively constructed with fiberglass-reinforced plastic or coated with a corrosion resistant material. These are widely used in corrosive applications and in high-temperature environments

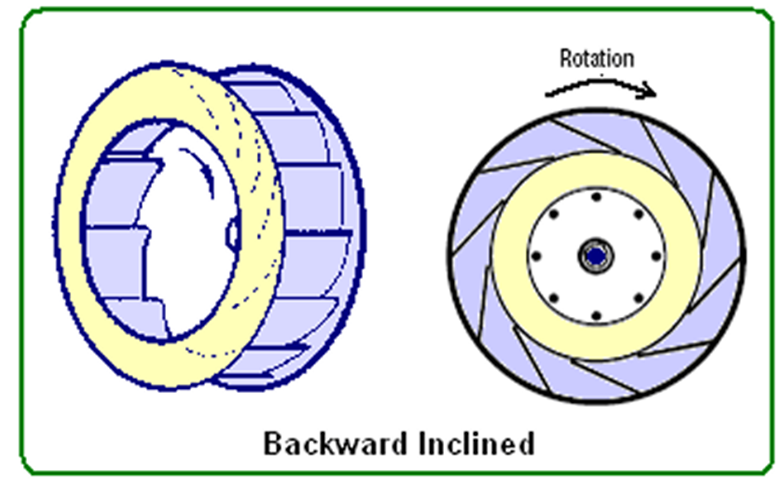

Backward inclined & Backward Curved Fans

Backward curved fans have blades with leading edge curved or inclined away from the direction of rotation.

- Backward curved fans have about 6 to 16 blades

- Backward inclined blade impellers produce air velocity slower than blade tip speed, but require greater rotational speed than forward curved types

- These fans run faster and require heavier, well-balanced construction. Larger shaft and bearing sizes are required for higher speeds. Because of this, proper wheel balance is more important.

- Up to 75 – 80 percent efficient. The high operating efficiencies available from this fan type can provide low system life-cycle costs

- Normally used for high capacity, high pressure applications where power savings may outweigh its higher first cost

- A common application for backward-inclined fans is forced-draft service. In these applications, the fan is exposed to the relatively clean airstream on the upstream side of the process

- Exhibit ‘non-overloading’ power characteristics. The motor brake horsepower increases with airflow for most of the performance curve but drops off at high airflow rates. Because of this characteristic, this fan type is often selected when system behavior at high airflow rates is uncertain

- Backward inclined shape promotes low velocity air across the blades and is susceptible to contaminant build-up. Only recommended for clean air streams containing no condensable fumes or vapors.

- Centrifugal fans of the backward-inclined blade design are of three general types: flat, curved and airfoil.Flat blade types are more robust while the curved-blade fans tend to be more efficient. Airfoil blades are the most efficient of all, capable of achieving efficiencies exceeding 85 percent.

- At the cost of more maintenance and some increase in mechanical noise, the airfoil and backward inclined fan types generate lower sound levels overall.

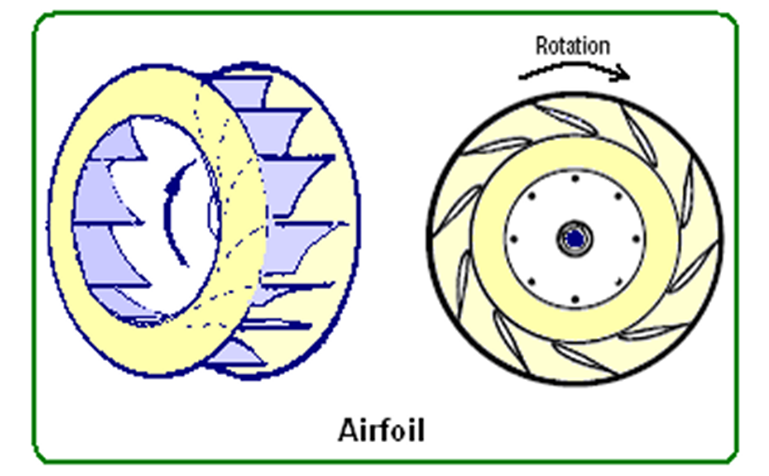

Airfoil fans

A variation of the backward inclined fan constructed of aerodynamic hollow profile blade, which makes these quieter and more efficient.

- Most efficient of all fan types and achieves the static efficiency is around 86-92 percent

- Have lower rotating mass due to thin wall blade construction, which makes them aerodynamically efficient. However, this thin walled characteristic makes this fan type highly susceptible to erosion problems

- For the given duty, the airfoil impeller design will provide for the highest speed of the centrifugal fan designs

- Airfoil fans have the highest initial cost and are suitable for clean air applications only. Airfoil blade is not recommended in corrosive and/or erosive environment unless blades are suitable coated

In summary,

| Parameters | Backward Curve | Backward Curve | Backward Curve | Forward Curve |

| Blades | 6-16 | 6-16 | 6-16 | 24-64 |

| Maximum Efficiency (%) | 78 | 85 | 90 | 70 |

| Speed | High | High | High | Low |

| Cost | Medium | Medium | High | Med-Low |

| Static Pressure | Very High | High | Very high (40in-wg) | Low (5 in-wg) |

| Power Curve | Non-overloading | Non-overloading | Non-overloading | Overloading |

| Housing | Scroll | Scroll | Scroll | Scroll |

Related Posts:

Centrifugal Fan Performance Curves

As you have known, you must know what the capacity of a fan is before you consider opening a damper or increasing the fan speed. Doing so may not be safe…

Different Types of Centrifugal Blower

Centrifugal blower may be classified into three basic types according to blade configuration: 1. Forward curve 2. Backward inclined 3. Radial or straight blade …