The term “system resistance” is used when referring to the static pressure. The system resistance is the sum of static pressure losses in the system. The system resistance is a function of the configuration of ducts, pickups, elbows and the pressure drops across Fans and Blowers equipment-for example bagfilter or cyclone. The system resistance varies with the square of the volume of air flowing through the system. For a given volume of air, the fan in a system with narrow ducts and multiple short radius elbows is going to have to work harder to overcome a greater system resistance than it would in a system with larger ducts and a minimum number of long radius turns. Long narrow ducts with many bends and twists will require more energy to pull the air through them. Consequently, for a given fan speed, the fan will be able to pull less air through this system than through a short system with no elbows. Thus, the system resistance increases substantially as the volume of air flowing through the system increases; square of air flow.

Conversely, resistance decreases as flow decreases. To determine what volume the fan will produce, it is therefore necessary to know the system resistance characteristics.

In existing systems, the system resistance can be measured. In systems that have been designed, but not built, the system resistance must be calculated. Typically a system resistance curve (see Figure 1.1) is generated with for various flow rates on the x-axis and the associated resistance on the y-axis.

Fan characteristics can be represented in form of fan curve(s). The fan curve is a performance curve for the particular fan under a specific set of conditions. The fan curve is a graphical representation of a number of inter-related parameters. Typically a curve will be developed for a given set of conditions usually including: fan volume, system static pressure, fan speed, and fan brake horsepower required to drive the fan under the stated conditions. Some fan curves will also include an efficiency curve so that a system designer will know where on that curve the fan will be operating under the chosen conditions (see Figure 1.2). In the many curves shown in the Figure, the curve static pressure (SP) vs. flow is especially important.

The intersection of the system curve and the static pressure curve defines the operating point. When the system resistance changes, the operating point also changes. Once the operating point is fixed, the power required could be found by following a vertical line that passes through the operating point to an intersection with the power (BHP) curve. A horizontal line drawn through the intersection with the power curve will lead to the required power on the right vertical axis. In the depicted curves, the fan efficiency curve is also presented.

System Characteristics and Fan Curves

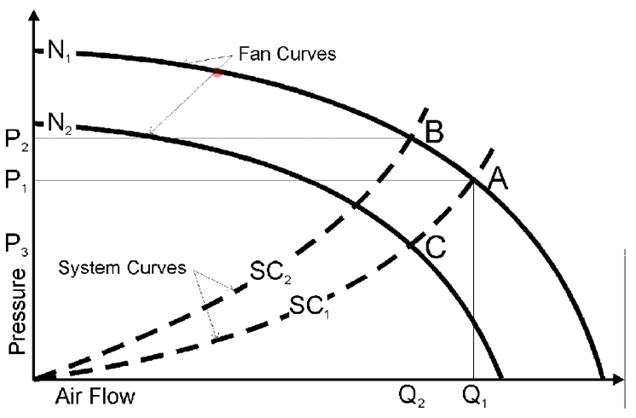

In any fan system, the resistance to air flow (pressure) increases when the flow of air is increased. As mentioned before, it varies as the square of the flow. The pressure required by a system over a range of flows can be determined and a “system performance curve” can be developed (shown as SC) (see Figure 1.3).

This system curve can then be plotted on the fan curve to show the fan’s actual operating point at “A” where the two curves (N1 and SC1) intersect. This operating point is at air flow Q1 delivered against pressure P1.

A fan operates along a performance given by the manufacturer for a particular fan speed. (The fan performance chart shows performance curves for a series of fan speeds.) At fan speed N1, the fan will operate along the N1 performance curve as shown in Figure 1.3. The fan’s actual operating point on this curve will depend on the system resistance; fan’s operating point at “A” is flow (Q1) against pressure (P1).

Two methods can be used to reduce air flow from Q1 to Q2:

First method is to restrict the air flow by partially closing a damper in the system. This action causes a new system performance curve (SC2) where the required pressure is greater for any given air flow. The fan will now operate at “B” to provide the reduced air flow Q2 against higher pressure P2.

Second method to reduce air flow is by reducing the speed from N1 to N2, keeping the damper fully open. The fan would operate at “C” to provide the same Q2 air flow, but at a lower pressure P3.

Thus, reducing the fan speed is a much more efficient method to decrease airflow since less power is required and less energy is consumed. The centrifugal fans operate under a predictable set of laws concerning speed, power and pressure. A change in speed (RPM) of any fan will predictably change the pressure rise and power necessary to operate it at the new RPM.

Related Posts:

Factors Affecting Fan Performance

Air Density (Temperature and Altitude) – Air density is a variable of elevation and temperature, and both these variables affect fan air performance. Air density will affect the total pressure that a fan can generate and…

Fan Energy Efficiency Opportunities

…as a general rule it is important to know that to effectively improve the performance of fan systems, designers and operators must understand how other system components function as well. The “systems approach” requires knowing…