Principle of Operation

Axial – Operate on the principle of deflection of airflow by the fan blade. The pressure is produced simply by the lift of the rotating blades as air moves over it. These types are characterized by the path of the airflow through the fan.

Key Characteristics

- Axial fans, as the name implies, move air parallel to the shaft, or axis, of the fan.

- Axial-flow fans impart energy to the air by giving it a twisting motion. The air is pressurized by the aerodynamic lift generated by the fan blades, much like a propeller and an airplane wing.

- Typically provide large air volumes at relatively low pressures.

- Key advantages are compactness, low cost, and lightweight.

- Axial fans are frequently used in exhaust applications where airborne particulate size is small, such as dust streams, smoke, and steam.

- Less bulky than a centrifugal fan of comparable capacity and have the advantage of straight through airflow

- Typically designed to generate flow in one direction but they can operate in the reverse direction. This characteristic is useful when a space may require contaminated air to be exhausted or fresh air to be supplied.

- Axial fans must rotate faster than comparable centrifugal fans to achieve the same airflow capacity. This characteristic makes them noisier than comparable centrifugal fans. However, high noise of axial fans tends to be dominated by high frequencies, which are easier to attenuate.

- Axial fans have a severe stall region that makes them particularly unsuitable for systems with widely varying operating conditions

- Axial fans have non-overloading power characteristic which enables the correct motor horsepower to be used for any particular fan or application without causing a burn-out due to overload

- Are available in both direct drive and belt drive options; belt drives offer an advantage by removing the motor from the airstream subjected to high level of contaminants otherwise for harsh applications with direct drive, sealed motor should be used.

As a general rule, axial fans are preferred for high volume, low pressure, and non-ducted systems. There are three main types

- Propeller

- Tube axial and

- Vane axial.

Propeller fans

- Have two or more blades that generate very high airflow volumes

- Low static pressure up to ¾ in-wg

- Can provide reversed air flow at reduced volumes and pressure by reversing the direction of rotation.

- Exhibit ‘overloading power’ characteristic i.e. the power required to drive the impeller continues to increase as the resistance to airflow increases

- Very low efficiencies of approximately 50 percent or less

- Light weight and inexpensive because of their simple construction

- Noise levels of the propeller fan are only slightly higher than those of the tubeaxial and vaneaxial fans, but such of the fan noise is at low frequencies and therefore is difficult to attenuate

- Primary applications include low pressure, high volume air moving applications such as air circulation within a space or ventilation through a wall without attached ductwork

- Used for replacement air applications. Ideal for exhaust applications and are often used in rooftop ventilation applications. Also used for make up or replacement air applications

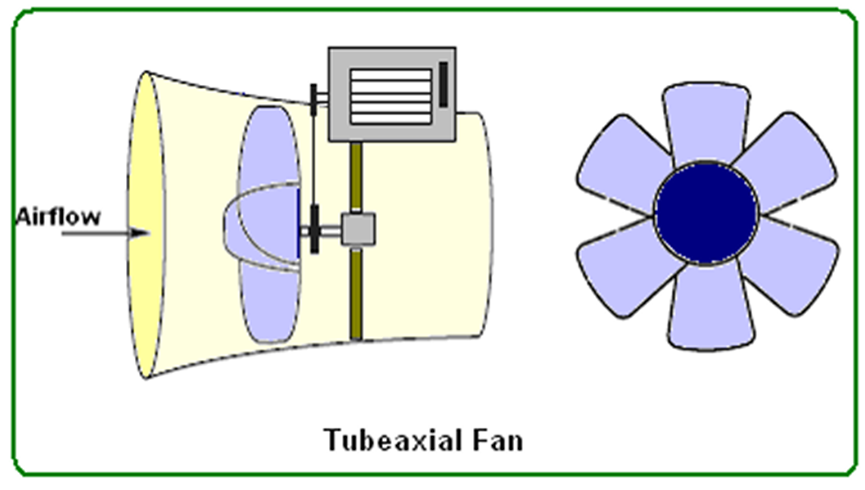

Tubeaxial fans

Tubeaxial fans have a wheel inside a cylindrical housing, with close clearance between blade and housing. Generally, the numbers of blades range from 4 to 8 with the hub normally less than 50 percent of fan tip diameter.

- Capable of developing a more useful static pressure range (to10 – 15in-wg)

- Capable of delivering operating efficiencies up to 75 percent

- The downstream profile is uneven with a large rotation component. This airflow characteristic is accompanied by moderate airflow noise.

- Suited for ducted applications where downstream velocity profiles is not very critical

- Most good design blades are aerofoil shaped

- Can be either connected directly to a motor or driven through a belt configuration. Because of the high operating speeds of 2-, 4-, and 6-pole motors, most tubeaxial fans use belt drives to achieve fan speeds below 1,100 revolutions per minute.

- Adjustable blade pitch fans allow capacity control

- Tubeaxial fan generates a somewhat higher noise level than the vaneaxial fan; its spectrum contains a very strong blade frequency component.

- Used in medium-pressure, high airflow rate applications and are frequently used in exhaust applications because they create sufficient pressure to overcome duct losses and are relatively space efficient. Also used in some industrial applications such as drying ovens, paint spray booths, and fume exhaust systems.

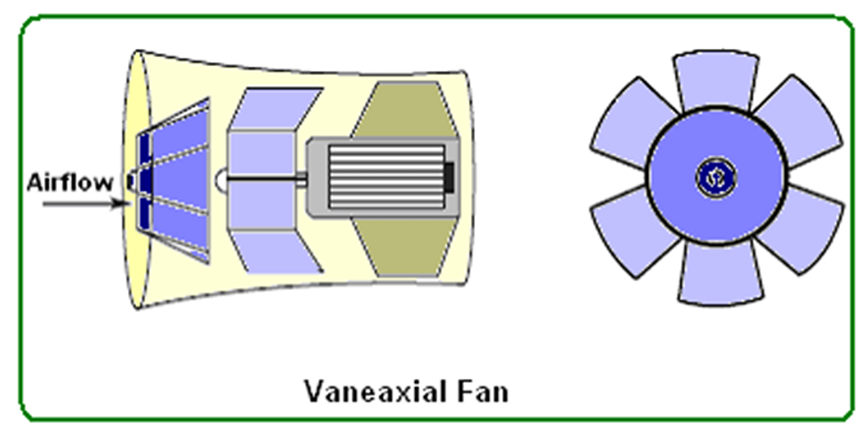

Vaneaxial Fans

Vane-axial fans are similar to tube-axial fans with guide vanes on down streamside to improve flow profile.

- Typically have 5 to 20 aerofoil type blades with a large hub diameter.

- Very close blade tip to housing clearance

- Blades are fixed or adjustable pitch types and the hub is usually greater than 50 percent of the fan tip diameter

- Very efficient. When equipped with airfoil blades and built with small clearances, they can achieve efficiencies up to 85 percent.

- High-pressure capability up to 8 in-wg. Custom equipment is capable of 20 -40 in-wg

- Typically, vaneaxial fans have performance curves that have unstable regions to the left of the peak pressure.

- Typically used in medium- to high-pressure applications, such as induced draft service for a boiler exhaust.

- Like tubeaxial fans, vaneaxial fans tend to have a low rotating mass, which allows them to achieve operating speed relatively quickly. This characteristic is useful in emergency ventilation applications where quick air removal or supply is required.

- Vaneaxial fans generate somewhat higher noise levels than ventilating centrifugal fans of comparable output.

- Adjustable pitch blades allow capacity control

In summary

| Parameters | Propellers | Tube Axial | Vane axial |

| Blades | 2 to 8 | 4 to 5 | 5 to 20 |

| Maximum Efficiency (%) | 50 | 75 | 85 |

| Speed | Medium | High | Very High |

| Cost | Low | Medium | High |

| Static Pressure | Low (up to ¾ in) | Medium | High (up to 8 in) |

| Power Curve | Non-overloading | Non-overloading | Non-overloading |

| Housing | Annular ring | Cylindrical | Cylindrical with guide vanes on downstream side |

Related Posts:

Introduction of Centrifugal Fan or Blower, and Axial Flow Fan

There are two basic types of air moving devices: the centrifugal fan or blower, and the axial flow fan. Generally speaking, the centrifugal fan creates higher pressures…

The Different Type of Fans’ System Effect Test

Tube Axial Fans Figures below illustrate how tube axial fans are tested. Fig #1 is typical of how tube axial fans are tested. AMCA refers to this …