Fan selection is a complex process that starts with a basic knowledge of system operating conditions: air properties (moisture content, temperature, density, contaminant level, etc.), airflow rate, pressure, and system layout. When selecting a fan, the following information must be known.

- Volume of air to be moved per unit time

- Static pressure-the estimated system resistance and expected variations

- Space avaliable for installing fans

- Amount of noise pemitted

- Efficiency-select fan that will deliver required volume at the expected static pressure with the minimum horsepower

- Economic considerations

These conditions determine which type of fan—centrifugal fan or axial fan —is required to meet service needs. After deciding which fan type is appropriate, the right size must be determined. Fans are usually selected on a “best-fit” basis rather than designed specifically for a particular application. A fan is chosen from a wide range of models based on its ability to meet the anticipated demands of a system. For any one-performance point, there are many different fans, which will satisfy that rating. However, based upon any one set of priorities such as fan size, efficiency, motor size etc., there is only one best fan for that application.

As an example, for a single operating point of 60,000 CFM at 7.0 inches total pressure at a density of .075 lbs/ft3 (70 degrees), several different fans will satisfy that rating. The possible selections are tabulated in the chart below taking into account impeller size, operating speed, horsepower, relative selling price and recommended motor size.

Influence of fan size and type 60,000 CFM at 7″ total pressure

| Item | Axial | Radial | Radial | Radial | Backward | Backward | Backward |

| Diameter | 48″ | 66″ | 60″ | 54″ | 66″ | 60″ | 54″ |

| Speed(rpm) | 1750 | 603 | 685 | 846 | 630 | 729 | 870 |

| Power(BHP) | 81.4 | 91.0 | 95.0 | 103 | 77.1 | 77.1 | 80.0 |

| Efficiency(%) | 81.0 | 72.5 | 69.5 | 64.0 | 85.5 | 85.5 | 82.5 |

| Cost Factor | 1.0 | 2.5 | 2.1 | 2.0 | 2.6 | 2.2 | 2.1 |

| Motor(hp) | 100 | 100 | 125 | 125 | 100 | 100 | 100 |

Depending upon which priority is chosen with regards to acceptability, the optimum fan selection will change.

- Based upon selling price the 48 inch axial fan would be selected. This fan is the cheapest of all, but the high RPM operation would increase the noise levels.

- Based upon operating costs, the 48-inch axial or the 60 inch backwardly inclined fan could be selected.

- If there was dust in the airstream, the radial tipped fan might be selected taking into account erosion. Plus these fans operate at low RPM; therefore the noise levels would be low.

- The optimum fan to satisfy the future rating would be the 48-inch axial utilizing a blade angle change since the centrifugal fan would have to be increased in speed sixteen percent with a corresponding horsepower increase of fifty-eight percent. The motor for the 48-inch axial would simply require better initial insulation so as to handle the increased power.

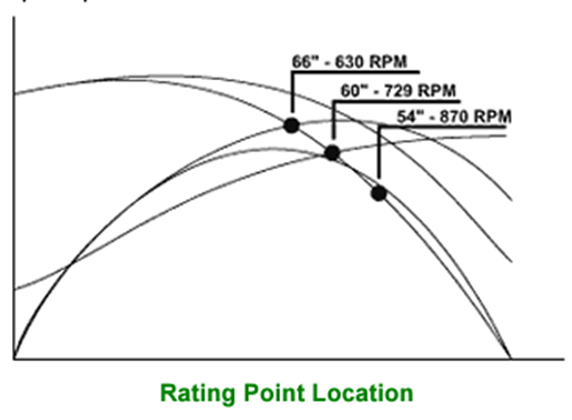

- Fan selection and rating point location: A very important concept is the relationship between size and the rating point location on the fan curve. The generic performance curve for the three backwardly curved fans from the chart is shown below. This figure illustrates that the relative position of the rating point on the fan curve changes with a change in fan size for a particular rating. As can be seen, the smaller the fan size used to satisfy a rating, the faster it must run and the farther it will be to the right on the fan curve. In general, it will also be less efficient. It will be louder and wear out faster. This concept is important when considering types of control and fan stability when operation is near peak pressure.

Fan selection is based on the static pressure for a given volume of air that needs to be moved. The example above provides clues for fan selection at fixed CFM and pressure. In actual practice the system pressure requirements are never exactly known. Take another example, for three different fans that are capable of supplying about 10,000 CFM (cubic feet per minute) of air.

Fan Rating Table for three fans supplying about 1000 CFM

| Item | Fan #1 | Fan # 2 | Fan # 3 |

| Diameter | 30” | 36” | 54” |

| Free air CFM | 10200 | 11700 | 29100 |

| 1/8” SP | 9200 | 10220 | 22300 |

Fan Rating Table for three fans supplying about 1000CFM

| Item | Fan #1 | Fan # 2 | Fan # 3 |

| ¼”SP | 7400 | 86900 | 14100 |

| 3/8 SP | 4300 | 7560 | 10400 |

| Fan RPM | 640 | 650 | 385 |

| Motor (hp) | 3/4 | 1 | 2 |

Inferences

- Fan # 1 delivers 10,200 CFM at conditions of free air. Free air means there is no static pressure. However, at 1/8” SP, the air flow rate drops to 9200 CFM and finally to 4300 CFM at 3/8” SP.

- Fan # 2 supplies 10,200 CFM at 1/8” SP and drops to 7560 CFM at 1/8” SP.

- Fan # 3 delivers much more than 10,000 CFM at all static pressures below 3/8” SP. Only at 3/8” SP does fan # 3 deliver 10,400 CFM.

For a desired airflow rate of 10000 CFM and the expected SP up to 1/8”, fan #2 is definitely the choice as it operates close to the best efficiency point. At 1/8” SP the fan #1 would not deliver enough air and fan #3 would deliver too much air.

Fan System Design Considerations

It is important to address the following questions related to system design:

- What is the application and what is the fan supposed to do?

- How many systems are there and are they interdependent?

- How many fans per system?

- Where is the fan equipment located (inside, outside, next to an office, on the ground or several stories up in a building?) If outside, what are the ambient conditions?

- What space limitations exist? Is there adequate space for fan maintenance and removal of parts?

- What facility limitations exist in the form of weight, electrical capability, noise or vibration?

- What fan orientation is best suited for the application?

- What fan arrangement is best suited for the application?

- What are the airstream characteristics? Is fan required to handle moisture, particulate or contaminants?

- Is the environment corrosive, flammable or hazardous?

- Are there any leakage requirements for the fan or ductwork?

- Are there any sound limitations including casing radiated or duct breakout noise?

- Are there any storage requirements? If so, how long and under what conditions?

- The cost of electricity and any support functions required?

Fan Life cycle considerations

- The overall effectiveness of the fan/system selection should be evaluated taking each of the following into account:Initial cost – What is the purchase price and cost of installation?

- Operating cost – What is the total cost per year to operate the fan, accessories and any support equipment?

- Maintenance – Is maintenance costly and frequent? And, is the equipment accessible for ease of maintenance?

- Frequency of repair and downtime – What is the reliability of the equipment and the cost of downtime?

- Spare parts – Are spare parts expensive and readily available? Must an inventory of spare parts be maintained?

- System availability – What percentage of time must the system be operable? There may be the requirement to have a “stand-by fan”.

- Expected life – What is the expected life of the equipment before it is to be replaced?

Related Posts:

Factors Determining Fan Selection

As we already know, fan selection is a complicated process that starts with a basic knowledge of system operating requirements and conditions such as airflow rates, temperatures, pressures, airstream properties, and…

Fan Design and Selection Criteria

Precise determination of air-flow and required outlet pressure are most important in proper selection of fan type and size. The air-flow required depends on the process requirements; normally determined from heat transfer rates, or…