This section describes the most important energy efficiency opportunities for fans and blowers.

Choose the right fan

Important considerations when selecting a fan are (US DOE, 1989):

- Noise

- Rotational speed

- Air stream characteristics

- Temperature range

- Variations in operating conditions

- Space constraints and system layout

- Purchase costs, operating costs (determined by efficiency and maintenance), and operating life

But as a geBut as a general rule it is important to know that to effectively improve the performance of fan systems, designers and operators must understand how other system components function as well. The “systems approach” requires knowing the interaction between fans, the equipment that supports fan operation, and the components that are served by fans. The use of a “systems approach” in the fan selection process will result in a quieter, more efficient, and more reliable system.

A common problem is that companies purchase oversized fans for their service requirements. They will not operate at their best efficiency point (BEP) and in extreme cases these fans may operate in an unstable manner because of the point of operation on the fan airflow pressure curve. Oversized fans generate excess flow energy, resulting in high fan airflow noise and increased stress on the fan and the system. Consequently, oversized fans not only cost more to purchase and to operate, they create avoidable system performance problems. Possible solutions include, amongst other replacing the fan, replacing the motor, or introducing a variable speed drive motor.

Reduce the system

resistance The system resistance curve and the fan curve were explained in section 1.2. The fan operates at a point where the system resistance curve and the fan curve intersects. The system resistance has a major role in determining the performance and efficiency of a fan. The system resistance also changes depending on the process. For example, the formation of the coatings / erosion of the lining in the ducts, changes the system resistance marginally. In some cases, the change of equipment, duct modifications, drastically shift the operating point, resulting in lower efficiency (See Figure 2). In such cases, to maintain the efficiency as before, the fan has to be changed.

Hence, the system resistance has to be periodically checked, more so when modifications are introduced and action taken accordingly, for efficient operation of the centrifugal fan.

Operate close to BEP

It is earlier described that the fan efficiency increases as the flow increases to certain point and thereafter it decreases. The point at which maximum efficiency is obtained is called the peak efficiency or “Best Efficiency Point” (BEP). Normally it is closer to the rated capacity of the fan at a particular designed speed and system resistance. Deviation from the BEP will result in increased loss and inefficiency.

Maintain fans regularly

Regular maintenance of fans is important to maintain their performance levels. Maintenance activities include (US DOE, 1989):

- Periodic inspection of all system components

- Bearing lubrication and replacement

- Belt tightening and replacement

- Motor repair or replacement

- Fan cleaning

Control the fan air blower

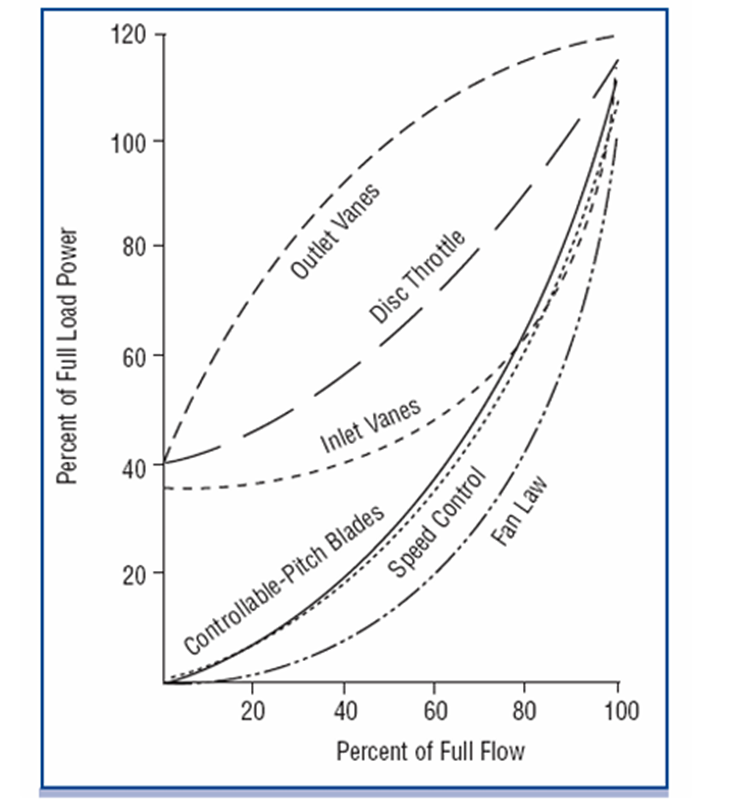

Normally, an installed fan operates at a constant speed. But some situations may require a speed change, for example more airflow may be needed from the fan when a new run of duct is added, or less air flow may be needed if the fan is oversized. There are several ways to reduce or control the airflow of fans. These are summarized in Table 5 and a comparison of full load power against percentage full flow by different flow control is given in Figure 1.

Figure 1. Relative Power Consumption among Flow Control Options (US DOE,1989)

| Type of flow control | Advantages | Disadvantages |

| Pulley change: reduces the motor / drive pulley size | ■ Permanent speed decrease ■ Real energy reduction (see Figure 2: a 2 inch reduction in pulley results in 12 kW savings) | ■ Fan must be able to handle capacity change ■ Fan must be driven by V-belt system or motor |

| Dampers: reduce the amount of flow and increases the upstream pressure, which reduces fan output | ■ Inexpensive ■ Easy to install | ■ Provide a limited amount of adjustment ■ Reduce the flow but not the energy consumption ■ Higher operating and maintenance costs |

| Inlet guide vanes: create swirls in the fan direction thereby lessening the angle between incoming air and fan blades, and thus lowering fan load, pressure and airflow | ■ Improve fan efficiency because both fan load and delivered airflow are reduced ■ Cost effective at airflows between 80-100% of full flow | Less efficient at airflows lower than 80% of full flow |

| Variable pitch fans: change the angle between incoming airflow and the blade by tilting the fan blades, thereby reducing both the motor load and airflow | ■ Can keep fan efficiency high over a range of operating conditions. ■ Avoid resonance problems as normal operating speed is maintained ■ Can operate from a no-flow to a full-flow condition without stall problems | ■ Applicable to some axial fan types only ■ Fouling problems if contaminants accumulate in the mechanical actuator that controls the blades ■ Operating at low loads for long periods reduces the power factor and motor efficiency, thus loosing efficiency advantages and risking low power factor charge from the utility |

| Variable Speed Drive (VSD): reducing the speed of motor of the fan to meet reduced flow requirements ■ Mechanical VSDs: hydraulic clutches, fluid couplings, and adjustable belts and pulleys ■ Electrical VSDs: eddy current clutches, wound-rotor motor controllers, and variable frequency drives (VFDs: change motor’s rotational speed by adjusting electrical frequency of power supplied) | ■ Most improved and efficient flow control ■ Allow fan speed adjustments over a continuous range For VFDs specifically ■ Effective and easy flow control ■ Improve fan operating efficiency over a wide range of operating conditions ■ Can be retrofitted to existing motors Compactness ■ No fouling problems ■ Reduce energy losses and costs by lowering overall system flow | ■ Mechanical VSDs have fouling problems ■ Investment costs can be a barrier |

| Multiple speed pump | ■ Efficient control of flow ■ Suitable if only two fixed speeds are required | ■ Need to jump from speed to speed ■ Investment costs can be a barrier |

| Disc throttle: a sliding throttle that changes the width of the impeller that is exposed to the air stream | ■ Simple design | ■ Feasible in some applications only |

| Operate fans in parallel: two or more fans in parallel instead of one large one | ■ High efficiencies across wide variations in system demand ■ Redundancy to mitigate the risk of downtime because of failure or unexpected maintenance ■ Two smaller fans are less expensive and offer better performance than one relatively large one ■ Can be equipped with other flow controls to increase flexibility and reliability | ■ Should only be used when the fans can operate in a low resistance almost in a free delivery condition (see Figure 3) |

| Operate fans in series: using multiple fans in a push-pull arrangement | ■ Lower average duct pressure ■ Lower noise generation ■ Lower structural and electrical support requirements ■ Suited for systems with long ducts, large pressure drops across system components, or high resistances | ■ Not suited for low resistance systems (see Figure 3) |

Table 1. Comparison of Different Ways to Control Fan Flow (adapted from US DOE, 1989, and BEE, 2004)

Figure 3.Fans Operating in Series and in Parallel (BEE India,2004)

Related Posts:

Fan efficiency shifts to the left, providing an essential cost advantage during periods of low system demand. Reducing fan speed can significantly reduce energy consumption…

…size and space restrictions, and overall cost. Typically, fan (and associated motor) selection is determined by the application or cost, while energy efficiency is a secondary driver…