Fans, consisting of multiple rotating blades powered by a motor, are used to move air in a variety of common residential and commercial applications. They are sold as part of a packed appliance (e.g., refrigerator) or building system (e.g., central heating and cooling) or independently (e.g., ceiling fan).

There are 2 basic types of fans: centrifugal fans and axial fans. The application dictates which type is preferable based on requirements for air flow, pressure increase, size and space restrictions, and overall cost. Typically, fan (and associated motor) selection is determined by the application or cost, while energy efficiency is a secondary driver. Figure 1-1&1-2 shows examples of both types of fans.

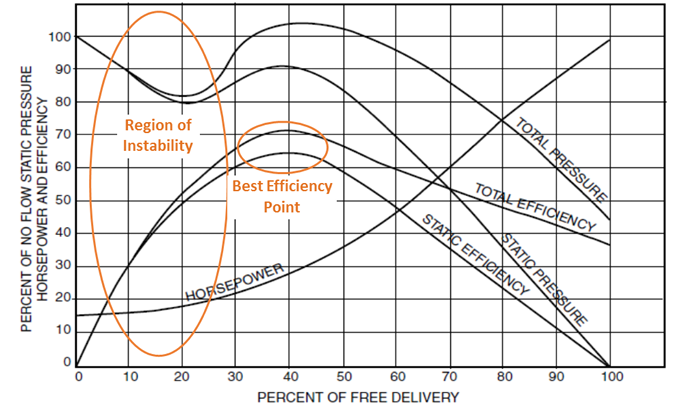

The DOE’s Rulemaking for Commercial and Industrial Fans and Blowers (CIF) characterizes these fan types.In this report does not describe the technology in depth, but does include them when estimating commercial fan energy consumption. Fan performance curves detail an individual fan’s delivered pressure, fan efficiency, and required power across its range of air flow. Figure 1-3 provides an example, with individual lines for pressure, efficiency, and power, all on a percentage-of-maximum air flow basis. The figure shows each line versus the “percent of free delivery,” which is the conditions that exist when there are no effective restrictions to air flow (no static pressure) at the fan’s inlet or outlet. System designers will aim for the system to operate at, or close to, the best efficiency point (BEP), where the fan operates most effectively in terms of total efficiency (delivered pressure and airflow divided by power consumption) and maintenance considerations. Operating a fan at higher OR lower percent of free delivery will lower efficiency, increases equipment wear, and increases fan noise. Such performance curves are unique to each fan and are essential to understand when selecting a fan.

As Figure 1-3 shows, fans can have a region of instability. A fan operating in a region of instability can cause increased noise and vibration. Extended operation in this region can result in an unstable, pulsating airflow that will lead to impeller and structural damage to the fan and ductwork or other system components. Within the region of instability, stall occurs when the fan is providing flows that are too small for its intended design. A stalling fan indicates that the fan might have been improperly sized given the backpressure in the system. Stalled fans might also indicate a problem in the system, such as an obstruction that leads to airflow restriction.

Both centrifugal and axial fans can be driven directly, where the motor and fan assembly share the same drive shaft, or indirectly, where the motor drives the fan assembly via an intermediary link, typically a belt. Direct drives are simpler and require less maintenance. However, fan speed is limited to the possible speeds of the motor. Where a variable speed drive is available, directly driven fans may be suitable. Indirect drives offers the flexibility to vary the fan speed compared to the motor speed by changing the gear ratio of the interconnecting belt. Both fan types may be used for both “clean” and “dirty” airstreams (high moisture and/or particulate content), and in higher temperature applications. Figure 1-4 shows a summary of applications for each fan type

Figure 1-4: Fan applications by type

Beyond centrifugal and axial fans, our manufacturers sell fans with other configurations, such as:

- Inline fans – A housed fan with a centrifugal impeller designed to be mounted between duct sections with air flowing in an axial direction at the fan inlet and outlet.

- Mixed-flow fans – A fan in which the fluid path through the impeller is between 20 and 70 degrees relative to the axis of rotation.

- Power roof ventilators – Powered roof ventilators can be axial or centrifugal fans within a weather-resistant housing and a base designed to fit over a roof or wall opening.

Related Posts:

Axial – Operate on the principle of deflection of airflow by the fan blade. The pressure is produced simply by the lift of the rotating blades as air moves over it. These types are characterized by the path of the airflow through the fan….

Centrifugal – Operating principle is a combination of deflection by the blades as well as the centrifugal force exerted on the air rotating with the wheel and thereby moving outward in a radial direction…