There are two basic types of air moving devices:the axial flow fan,and the centrifugal fan or blower,. Generally speaking, the centrifugal fan creates higher pressures than that of the axial flow fan and is applied on jobs with higher resistance to the air flow.

Axial Flow Fan. There are three basic types of axial flow fans: The propeller fan, the tube-axial fan and the vane-axial fan. The first of these is probably the most familiar. The propeller fan consists of a propeller blade and an associated aperture to restrict “blow-back” from the output side. Without the aperture, the fan is not truly a propeller fan, since it cannot positively move air from one space to another. The aperture is usually sheet metal, designed to fit closely around the periphery of the propeller. The tube-axial fan is literally a propeller fan in a tube. In this case the tube replaces the aperture. The tube-axial fan, an extension of the propeller fan, increases flow quantity, pressure and efficiency, due to the reduced air leakage at the blade tips. The vane-axial fan is a tube-axial fan with the addition of vanes within the tube to straighten out the air flow. The air flow changes from helical flow imparted by the propeller into a more nearly straight line flow and, in the process, increases the pressure and efficiency while reducing noise.

In general, the propeller fan operates at the lowest pressure. The tube-axial fan is somewhat higher; and the vane axial fan supplies the highest pressure output of the three. Vane axial fans are used when available space for fan installation is limited.

Static efficiencies of 70 to 72 % are achieved with vane axial fans. The cfm and static performance range of the vane axial fan is similar to that of the BI and airfoil fans.

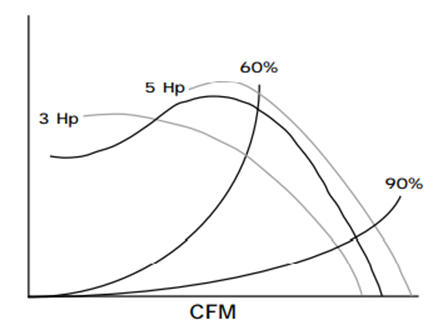

Similar to the BI fan, the horsepower lines are essentially parallel to the fan curves, therefore the vane axial fan, shown in Figure 1, is considered a non-overloading design.

Centrifugal Fan or Blower. The centrifugal fan consists of a wheel with small blades on the circumference and a shroud to direct and control the air flow into the center of the wheel and out at the periphery. The blades move the air by centrifugal force, literally throwing the air out of the wheel at the periphery, creating a suction inside the wheel. The basic types of wheel blades in centrifugal blowers are forward-curved (FC) and backward-inclined (BI). A centrifugal blower with forward-curved blades has blades that are curved in the direction of wheel rotation and, is primarily an impulse device. It accelerates the air to a high velocity, while rotating at a speed that is usually low compared to that of a backward-inclined blower. The forward-curved type is known as a “volume” blower, and is more common because it delivers the greatest air volume in relation to blower size and speed. It has static efficiency in the range of 60 to 68%.

FC blower wheels are operated at relatively low speeds and are used to deliver large air volumes against relatively low static pressures. The inherently light construction of the forward curved blade does not permit this wheel to be operated at speeds needed to generate high static pressures.

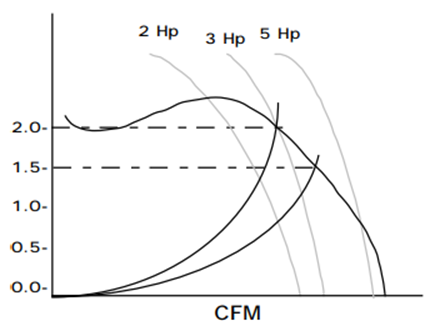

Notice in Figure 2 on this typical FC fan curve, how the brake horsepower lines cross the fan performance curves. Therefore, if the system resistance were to drop from 2 inches to 1.5 inches of static, in this example, the fan brake horsepower requirement would rise from 3 bhp to something over 3.5 bhp, possibly overloading the motor. Consequently, the FC fan is referred to as an overloading type fan.

The backward inclined blower wheel design has blades that are slanted away from the direction of wheel travel. The term applied to this type of blading is BI or backward inclined. (An AF fan, or air foil fan, is a subset of the BI fan with, as the name implies, more efficient fan blades.)

The performance of this wheel is characterized by high efficiency, high cfm inflatable air blower and its rugged construction makes it suitable for high static pressure applications.

The maximum static efficiency of the BI wheel is approximately 75 to 80 %. When a BI fan is selected to handle a given air quantity, it must be operated at approximately twice the speed of a similarly selected FC fan. In spite of this, the horsepower requirement of the BI fan is less, making it a more efficient design.

Unlike the FC fan, the brake horsepower lines of a BI fan are, for the most part, parallel to the fan performance curves. Therefore, if the system resistance were to drop from 4 to 2 inches static, as in Figure 3, the fan brake horsepower would change only slightly. For this reason, BI fans are referred to as non-overloading fans.

Related Posts:

Overview of Centrifugal Fan Types

A typical supply fan or impeller (wheel) can be described by the blade constructions. The distinguishing characteristic is the shape of the individual fan blades and their orientation relative to wheel rotation…

The words “fan” and “blower” are frequently used interchangeably. In HVAC/R terminology, the term fan may refer to any device used to create artificial currents of air. A blower is generally considered to be a particular type of …