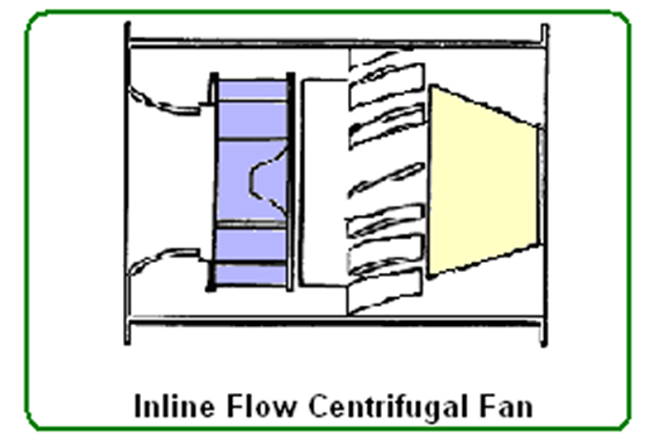

Inline flow centrifugal fans

This type of fan has backward-curved blades and a special housing that permits a space-saving straight-line duct installation. The wheel is very similar to that of the airfoil. Space requirements are similar to a vane axial fan.

Key Characteristics

- BC/BI impeller inside a tubular casing to produce flow inline with wheel axis and duct

- Also known as tubular centrifugal fans

- Absence of scroll housing makes these fans compact

- Small size fans have impeller mounted directly on motor and placed inside a spun aluminum casing split in two halves

- Typically used in low pressure return air or exhaust applications

Power roof ventilators

The objective of these ventilators is to produce a high-volume flow rate at low pressure. They can be of centrifugal fan or axial fan.

Key characteristics

- Roof top mounted exhaust

- BC/BI wheel or axial blade

- Vertically mounted on motor shaft

- Air discharged in a radial or axial direction 5) BC wheels quieter than axial blades

- Now housing but a weather protection casing made of spun aluminum or sheet fabrication

Plug / Plenum Fans

Like inline centrifugal fans, plug / plenum fans also use a BC (or AF) impeller but without the tubular casing.

Key characteristics

- Impeller / motor assemble placed inside a plenum which may contain coils and filters in case of an air-handling unit

- Air enters through a well designed circular inlet cone and comes out of the impeller in a radial direction

- Because of the absence of scroll housing, efficiencies are much lower than BC/BI fans

- Lower initial cost makes them popular choice in clean room applications

Common Blower Types

Blowers can achieve much higher pressures than centrifugal fans, as high as 20psi. They are also used to produce negative pressures for industrial vacuum systems. Industrial air blowers look more like centrifugal pumps than fans. The impeller is typically gear-driven and rotates as fast as 15,000 rpm. In inflatable air blowers,air is accelerated as it passes through each impeller, although larger single-stage blowers can be more efficient because the air does not have to take as many turns.

- Centrifugal blowers typically operate against pressures of 5 to 10psi, but can achieve higher pressures. One characteristic is that airflow tends to drop drastically as system pressure increases, which can be a disadvantage in material conveying systems that depend on a steady air volume. Because of this, they are most often used in applications that are not prone to clogging.

- Positive-displacement blowers have rotors, which “trap” air and push it through housing. A “helical screw blower” uses two screw-shaped rotors. Positive-displacement blowers provide a constant volume of air even if the system pressure varies. They are especially suitable for applications prone to clogging, since they can produce enough pressure – typically up to 18psi – to blow clogged materials free. They turn much slower than centrifugal blowers (e.g. 3,600 rpm), and are often belt driven to facilitate speed changes.

Related Posts:

INTRODUCTION The words “fan” and “blower” are frequently used interchangeably. In HVAC/R terminology, the term fan may refer to any device used to create artificial currents of air. A blower is generally considered to be a particular type of …

Introduction of Centrifugal Fan or Blower, and Axial Flow Fan

There are two basic types of air moving devices: the centrifugal fan or blower, and the axial flow fan. Generally speaking, the centrifugal fan creates higher pressures than that of the axial flow fan and is applied on jobs with higher resistance to…