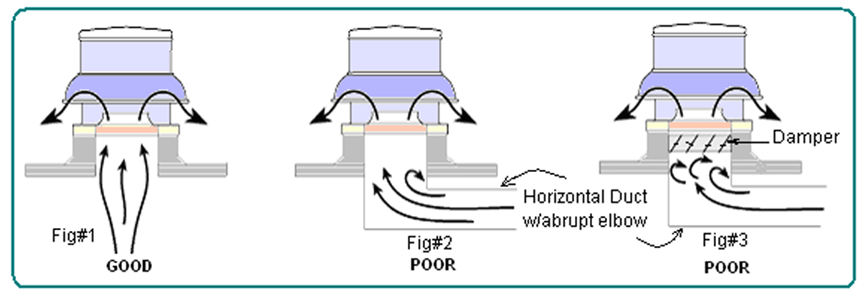

Roof Exhaust Fans

Figures below illustrate how roof exhausters are tested; AMCA refers to Fig#1 setup as “Type A: Free inlet, free outlet”. Fig # 2&3 illustrate roof exhaust fan installations having system effects. Fig # 3 illustrates the worst case, because the damper is located in a turbulent airstream. To improve on installations where horizontal ducts are used directly under the roofline, turning vanes should be installed in the elbows. In addition, a higher curb or extended base should be used. Higher curbs result in the elbow being further from the damper and fan inlet.

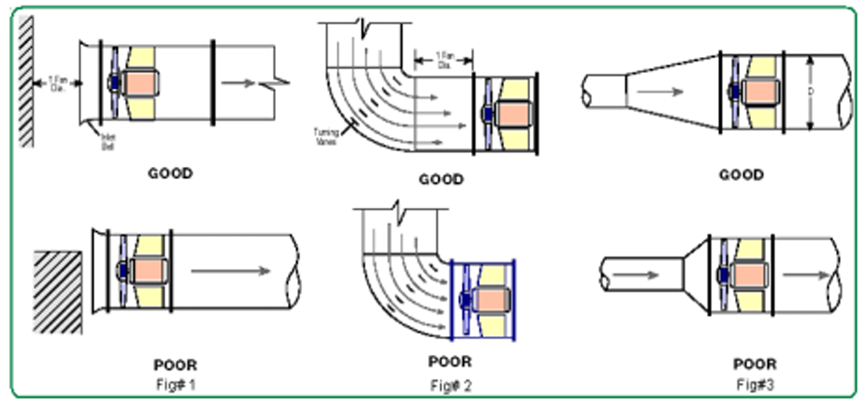

Tube Axial Fans

Figures below illustrate how tube axial fans are tested. Fig #1 is typical of how tube axial fans are tested. AMCA refers to this set-up as “Type B: Free inlet, ducted outlet.” Fig # 2 illustrates a good/poor installation with an elbow directly at the fan inlet. The air entering the fan is forced to one side.

Fig # 3 illustrates good/poor installation with ducted fan inlet.

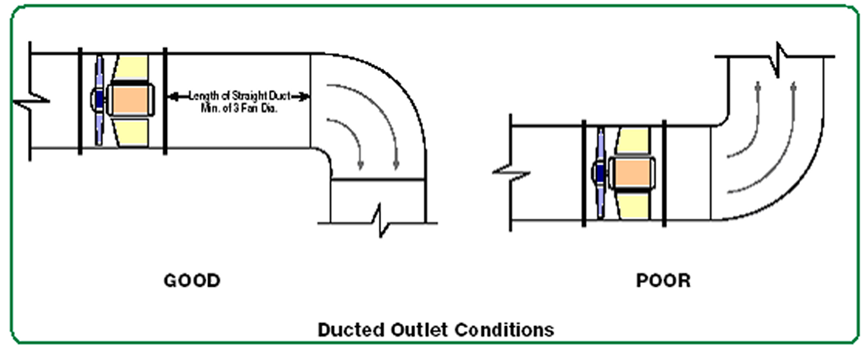

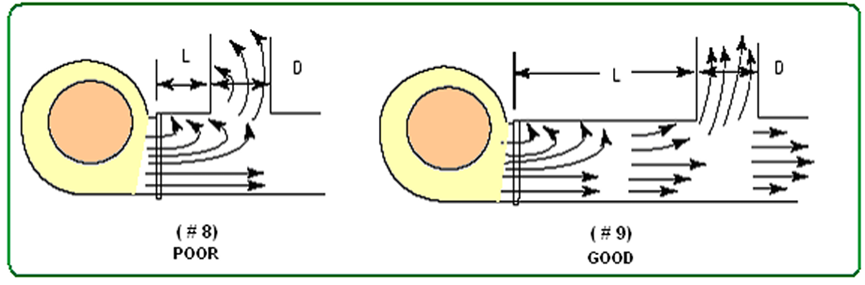

Installations with straight inlet ducts and inlet bells would result in similar Installations with straight inlet ducts and inlet bells would result in similar performance. Without a discharge duct, a system effect will occur. Inline installations are subject to system effect both at the fan inlet and outlet. Figure below illustrates a good/poor installation with discharge elbow directly at the fan outlet. Inline fans require the appropriate length of discharge duct in order to achieve cataloged performance.

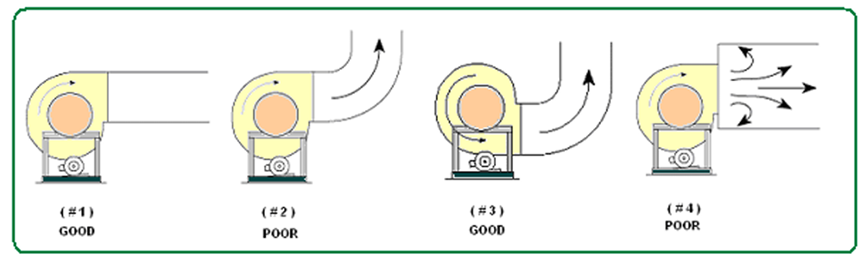

Centrifugal Fans

Centrifugal fan installations are subject to the greatest possibilities of system effect due to the possibilities of ducted inlets and outlets, plus multiple available arrangements, discharge positions, and clockwise and counter-clockwise rotations. Fig # 1 illustrates how housed centrifugal fans are tested. Fig # 1 is typical of how centrifugal fans are tested. AMCA refers to this set up as “Type B: free inlet, ducted outlet.” Fig # 2 illustrates a poor installation with an elbow directly at the fan discharge. This type of installation can be avoided by selecting a fan with the correct rotation and discharge position as shown in Fig # 3. Fig # 4 illustrates a poor installation with an abrupt discharge into a plenum.

Figure 4 illustrates another poor installation with an abrupt discharge into a plenum. A system effect results if a given length of discharge duct is not present.

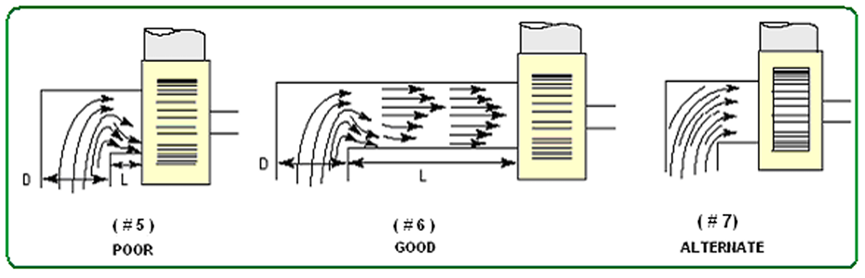

Fig # 5 illustrates installation with improper inlet conditions with an elbow directly at the fan inlet. Fig # 5 could be improved by ensuring L > 3D (refer Fig # 6). If this is not possible, the fan should be equipped with a factory inlet box or alternately, a flow straightener should be considered. Fig # 7 shows round baffles incorporated in the duct as an alternate measure.

The illustrations above show only a few of the many installation possibilities that can cause system effect. It is important to realize that fan manufacturers can only guarantee the fan to perform as tested. In the figures shown, not one of the fans is tested with obstructions, such as elbows, guards or dampers, directly at the fan inlet or outlet. These obstructions cause additional losses that are not included in the fan manufacturer’s tests, and in many cases, are not included in the designers’ usual system resistance calculations. AMCA Publication 210 shows four basic installation types. However, combining all the fan types, fan arrangements, and manufacturer’s choice of how to test, the installation possibilities are far too numerous to cover in this article.

In summary, here are a few points to consider:

- At the design stage, don’t try to save a few dollars per square foot of space. The cost of the resulting poor installation could be much greater.

- Carefully design the fan system so it can operate as intended. Personnel doing the installation and checkout should also be familiar with causes of system effect.

- In correcting installations with system effect, changing the ductwork should not be the last consideration. Remember the penalties of system effect will remain for the life of the project.

- Use a straight duct length on the discharge of both inline and centrifugal fans. In order to achieve a uniform velocity profile, a 100% effective duct length must be used. To calculate the 100% effective length, use 2.5 duct diameters for 2500 FPM (or less). Add one duct diameter for each additional 1000 FPM.

- In many cases an installation will end up having an obstruction at the inlet or outlet (or both) causing system effect. If these situations cannot be avoided at the design stage, the system effect should be estimated and added to the calculated system resistance.

- In general

- Roof exhaust fans are affected by the inlet condition.

- Roof supply fans are affected by outlet conditions.

- Fan types typically affected by both inlet and outlet conditions are inline fans (both axial and centrifugal) and housed single inlet centrifugal fans.

Related Posts:

Imagine a fan selected with great care to provide exactly the performance required in the specifications. Once installed, the air balancer reports that air performance is considerably lower than required. What went wrong?

Factors Affecting Fan Performance

Air density is a variable of elevation and temperature, and both these variables affect fan air performance. Air density will affect the total pressure that a fan can generate and the horsepower required to move the air.