Introduction

Fans and blowers provide air for ventilation and industrial process requirements. Fans generate a pressure to move air (or gases) against a resistance caused by ducts, dampers, or other components in a fan system. The fan rotor receives energy from a rotating shaft and transmits it to the air.

Difference between Fans, Blowers and Compressors

Fans, blowers and compressors are differentiated by the method used to move the air, and by the system pressure they must operate against. As per American Society of Mechanical Engineers (ASME) the specific ratio – the ratio of the discharge pressure over the suction pressure – is used for defining the fans, blowers and compressors (see Table 1.1).

| Equipment | Specific Ratio | Pressure rise (mmWg) |

| Fans | Up to 1.11 | 1136 |

| Blowers | 1.11 to 1.20 | 1136-2066 |

| Compressors | More than 1.20 | – |

Fan Types

Fan and blower selection depends on the volume flow rate, pressure, type of material handled, space limitations, and efficiency. Fan efficiencies differ from design to design and also by types. Typical ranges of fan efficiencies are given in Table 1.2.

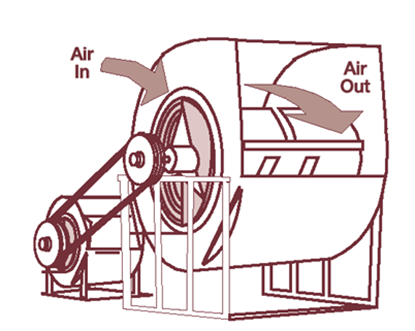

Fans fall into two general categories: centrifugal flow and axial flow.

In centrifugal flow, airflow changes direction twice – once when entering and second when leaving (forward curved, backward curved or inclined, radial) (see Figure 1.1).

| Type of fan | Peak Efficiency Range |

| Centrifugal Fan | |

| Airfoil, backward curved/inclined | 79-83 |

| Modified radial | 72-79 |

| Radial | 69-75 |

| Pressure blower | 58-68 |

| Forward curved | 60-65 |

| Axial fan | |

| Vanaxial | 78-85 |

| Tubeaxial | 67-72 |

| Propeller | 45-50 |

In axial flow, air enters and leaves the fan with no change in direction (propeller, tubeaxial, vaneaxial) (see Figure 1.2).

Centrifugal Fan: Types

The major types of centrifugal fan are: radial, forward curved and backward curved (see Figure 1.3).

Radial fans are industrial workhorses because of their high static pressures (up to 1400 mm WC) and ability to handle heavily contaminated airstreams. Because of their simple design, radial fans are well suited for high temperatures and medium blade tip speeds.Forward-curved fans are used in clean environments and operate at lower temperatures.They are well suited for low tip speed and high-airflow work – they are best suited for moving large volumes of air against relatively low pressures.

Backward-inclined fans are more efficient than forward-curved fans. Back-ward-inclined fans reach their peak power consumption and then power demand drops off well within their useable airflow range. Backward-inclined fans are known as “non-overloading” because changes in static pressure do not overload the motor.

| Paddle Blade (Radial blade) | Forward Curved (Multi-Vane) | Backward Curved |

|  |  |

The different types of fans, their characteristics and typical applications are given in Table 1.3.

Axial Flow Fan: Types

The major types of axial flow fans are:tube axial, vane axial and propeller (see Figure 1.4.) Tubeaxial fans have a wheel inside a cylindrical housing, with close clearance between blade and housing to improve airflow efficiency. The wheel turn faster than propeller fans, enabling operation under high-pressures 250 – 400 mm WC. The efficiency is up to 65%. Vaneaxial fans are similar to tubeaxials, but with addition of guide vanes that improve efficiency by directing and straightening the flow. As a result, they have a higher static pressure with less dependence on the duct static pressure. Such fans are used generally forpressures up to 500 mmWC. Vaneaxials are typically the most energy-efficient centrifugal fans and should be used whenever possible.

Propeller fans usually run at low speeds and moderate temperatures. They experience a large change in airflow with small changes in static pressure. They handle large volumes of air at low pressure or free delivery. Propeller fans are often used indoors as exhaust fans. Outdoor applications include air-cooled condensers and cooling towers. Efficiency is low – approximately 50% or less.

| Tube Axial | Vane Axial | Propeller |

|  |  |

|  |  |

Common Blower Types

Blowers can achieve much higher pressures than fans, as high as 1.20 kg/cm2. They are also used to produce negative pressures for industrial air blower. Major types are: centrifugal blower and positive-displacement blower.

Centrifugal blowers look more like centrifugal pumps than fans. The impeller is typically gear-driven and rotates as fast as 15,000 rpm. In multi-stage blowers, air is accelerated as it passes through each impeller. In single-stage blower, air does not take many turns, and hence it is more efficient.Centrifugal blowers typically operate against pressures of 0.35 to 0.70 kg/cm2, but can achieve higher pressures. One characteristic is that airflow tends to drop drastically as system pressure increases, which can be a disadvantage in material conveying systems that depend on a steady air volume. Because of this, they are most often used in applications that are not prone to clogging.Positive-displacement blowers have rotors, which “trap” air and push it through housing. Positive-displacement blowers provide a constant volume of air even if the system pressure varies. They are especially suitable for applications prone to clogging, since they can produce enough pressure – typically up to 1.25 kg/cm2 – to blow clogged materials free. They turn much slower than centrifugal blowers (e.g. 3,600 rpm), and are often belt driven to facilitate speed changes.

| Centrifugal fans | Axial-flow Fans | ||||

| Type | Characteristics | Typeical Applications | Type | Characteristics | Typical Applications |

| Radial | Highe preesure,medium flow,efficiency close to tube-axial fans,power increases continuously | Various industrial applications, suitable for dust laden, moist air/gases | Propeller | Low pressure, high flow, low efficiency, peak efficiency close to point of free air delivery (zero static pressure) | Air-circulation, ventilation, exhaust |

| Forward-curved blades | Medium pressure, high flow, dip in pressure curve, efficiency higher than radial fans, power rises continuously | Low pressure HVAC, packaged units, suitable for clean and dust laden air / gases | Tube-axial | Medium pressure, high flow, higher efficiency than propeller type, dip in pressure-flow curve before peak pressure point. | HVAC, drying ovens, exhaust systems |

| Backward curved blades | High pressure, high flow, high efficiency, power reduces as flow increases beyond point of highest efficiency | HVAC, various industrial applications, forced draft fans, etc. | Vane | High pressure, medium flow, dip in pressure-flow curve, use of guide vanes improves efficiency | High pressure applications including HVAC systems, exhausts |

| Airfoil type | Same as backward curved type, highest efficiency | Same as backward curved, but for clean air applications |

Related Posts:

Introduction of Centrifugal Fan or Blower, and Axial Flow Fan

There are two basic types of air moving devices: the centrifugal fan or blower, and the axial flow fan. Generally speaking, the centrifugal fan creates higher pressures than that of…

The words “fan” and “blower” are frequently used interchangeably. In HVAC/R terminology, the term fan may refer to any device used to create artificial currents of air. A blower is generally considered to be a particular…