Blowers are one of the mechanisms used regularly in submarines. They are installed in ventilation and air conditioning systems in almost all submarine compartments. Ventilation systems usually presented by central systems include supply and exhaust fans, serve for ventilation of accommodation and other than accommodation areas with atmospheric air with simultaneous ventilation of storage batteries and for air cooling and purification from harmful and smelling impurities. Air conditioning systems are presented by local, compartment group and single duct systems. These systems are used to provide comfortable conditions in terms of air temperature and humidity for the crew in accommodation areas, air purification in galleys, provision rooms, and sanitary areas and also for air mixing in compartments.

TYPES:

The two most common types of Centrifugal Blowers are

- Pressure Blowers

- Volume Blowers

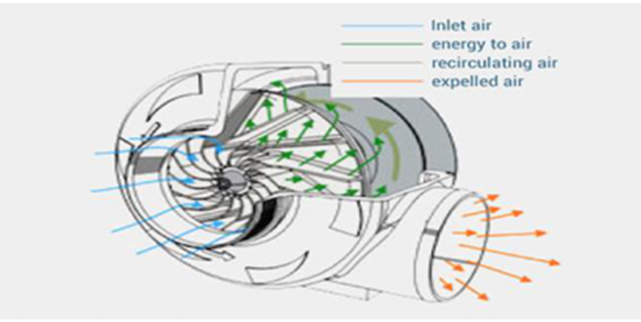

CENTRIFUGAL BLOWER OPERATING PRINCIPLE:

The centrifugal blower operating principle is similar to centrifugal fan, but the pneumatic compaction process usually passes several job impellers or several grades Carry on under the at odds with the community or the leadership action of force. The 1.5kW inflatable air blower has a high-speed trochanter rotated, the blade at the trochanter drives the high-speed sports of air, the centrifugal force makes the air flow into the air blower and export along the involute in the chassis of the involute shape, the high-speed air current has certain wind pressure. It is supplemented that the new air is entered by the centre of the chassis.

Also used to produce negative pressures for industrial air blower

- Major types are centrifugal blower and positive displacement blower

- The impeller is typically gear-driven and rotates as fast as 15,000 rpm

- Efficiency drops with multi-staging staging due to the path taken from stage to stage

- One characteristic is that airflow tends to drop drastically as system pressure increases

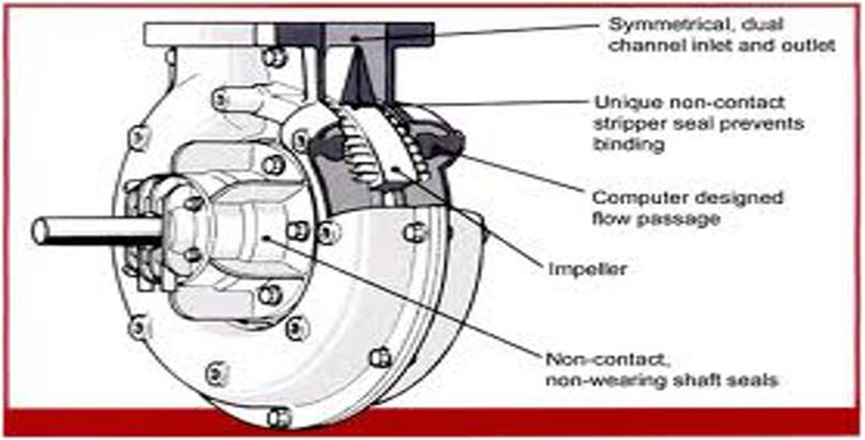

- Positive Positive-displacement displacement blowers have rotors, which “trap” air and push it through housing

- Positive-displacement blowers provide a constant volume of air even if the system pressure varies. They are especially suitable for applications prone to clogging.They turn much slower than centrifugal blowers (e.g. 3,600 rpm), and are often belt driven to facilitate speed changes

CENTRIFUGAL BLOWER WORKS:

A centrifugal blower has several; fan blades that are mounted around a hub, which turns on a driveshaft that goes directly through the housing of the blower. The gas will penetrate from the fan wheel side, than will turn 90 degrees and then will accelerate. This process is possible because the centrifugal force will flow over the fan blades and will exit through the fan housing.

SCOPE AND OBJECTIVE OF PRESENT WORK:

The Contemporary blades in Centrifugal Blower used in naval applications are made up of Aluminum or Steel. The objective of present work is to design a impeller of a blower with four materials.

Which are:

- Aluminum Alloy 1060

- Graphite

- Titanium

- E-glass/Epoxy

BLOWER POWER CALCULATION:

Blowers can be categorized as either (1) positive displacement blowers, which provide a constant volume of air at a wide range of discharge pressures, or (2) centrifugal blowers, which provide a wide range of flow rates over a narrow range of discharge pressure (USEPA, 2010). Table 1 summarizes the types of blowers in each category and provides information on operation, air flow rates, advantages, and disadvantages Metric unit – For volumetric air flow

Pw(kW)=QairP1/17.4eMeB*[(P2/P1)0.283-1](1)

Pw(hp)=QairP1/66.4eMeB*[(P2/P1)0.283-1](2)

Pw(kW)=WPT1/8.41eMeB*[(P2/P1)0.283-1](3)

Pw(hp)=WPT1/156eMeB*[(P2/P1)0.283-1] (4)

| Blower Type | Nominal Blower Efficiency(%) | Nominal Turndown(% of reated flopw) |

| Positive displacement (variable speed) | 40-65 | 50 |

| Multistage centrifugal (inlet throttled) | 50-70 | 60 |

| Multistage centrifugal (variable speed) | 60-70 | 50 |

| Single-stage centrifugal, integrally geared (with inlet guide vanes and variable diffuser vanes) | 70-80 | 45 |

| Single-stage centrifugal, gearless (high speed turbo) | 79-80 | 50 |

APPLICATIONS OF CENTRIFUGAL BLOWER:

Centrifugal blowers work for applications such as heating a furnace with hot air where a large air volume is required to fill the space. This includes:

- Climate control

- Cooling machinery

- Dryers

- Dust collectors

- Exhausting gases and vapours

- Filter installations

OPERATION:

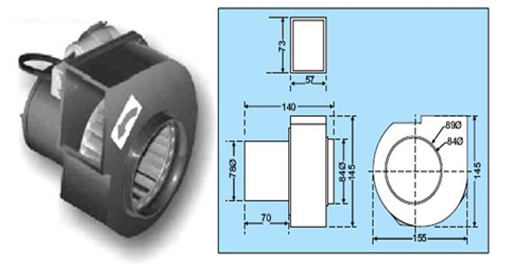

Voltage and Power Selection:

The voltage, frequency and phase of the power supply must be consistent with the motor nameplate rating.

- The motor will operate satisfactorily on voltages within 10% of the nameplate value or frequency within 5%. The combined variation must not exceed 10%.

The Allegro blowers are designed to operate from a grounded, 115 VAC 60Hz single phase power source.

Related Posts:

Inline flow centrifugal fans This type of fan has backward-curved blades and a special housing that permits a space-saving straight-line duct installation.

Centrifugal Fan Performance Curves

As you have known, you must know what the capacity of a fan is before you consider opening a damper or increasing the fan speed. Doing so may not be safe…